What is an outdoor optical cable? What are the laying methods for outdoor optical cables?

Outdoor optical cable is a cable formed by optical fiber (optical transmission carrier) through a certain process. Simply put, optical cable used outdoors is a kind of optical cable. Because it is most suitable for outdoor use, it is called outdoor optical cable. It is durable and durable. , Can withstand the wind, sun, cold and ground, the outer packaging is thick, with some mechanical and environmental characteristics such as pressure resistance, corrosion resistance, and tensile resistance. So what are the laying methods for outdoor optical cables?

Since its application in the 1970s, communication optical cables have developed into long-distance trunk lines, intra-city telephone relays, underwater and submarine communications, as well as local area networks, private networks and other wired transmission backbones, and have begun to develop into user access networks, from optical fibers to roads. Edge (FTTC), fiber to the building (FTTB), etc. are developing towards fiber to the home (FTTH). For various applications and environmental conditions, communication optical cables have overhead, direct buried, pipeline, underwater, indoor and other laying methods.

Overhead optical cable is an optical cable used on poles. This kind of laying method can use the original overhead open wire pole road, saving construction costs and shortening the construction period. Overhead optical cables are hung on electric poles and are required to be able to adapt to various natural environments. There are two ways to lay overhead optical cables: hanging wire and self-supporting. The suspension wire type is to fasten the cable on the pole with a suspension wire, and then hang the optical cable on the suspension wire with a hook. The load of the optical cable is carried by the suspension wire. The self-supporting type uses a self-supporting structure of the optical cable, and the optical cable is in the shape of "8". Type, the upper part is self-supporting line, and the load of the optical cable is carried by the self-supporting line.

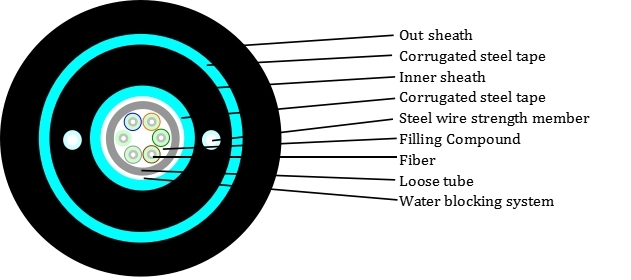

Directly buried optical cable. This optical cable has a steel belt or steel wire armor outside, and is directly buried underground. It requires the performance of resisting external mechanical damage and the performance of preventing soil corrosion. Different protective layer structures should be selected according to different use environments and conditions. For example, in areas with pests and rats, optical cables with protective layers that prevent pests and rats should be used. Depending on the soil and the environment, the depth of the fiber optic cable buried in the ground is generally between 0.8m and 1.2m. During laying, care must also be taken to keep the strain of the optical fiber within the allowable limit.

The laying of pipeline optical cables is generally in urban areas, and the environment for pipeline laying is relatively good, so there are no special requirements for the optical cable sheath, and no armoring is required. The materials for the pipes can be selected from concrete, asbestos cement, steel pipes, plastic pipes, etc. according to geography.

Underwater optical cable is an optical cable that radiates under water and crosses rivers, lakes and beaches. The laying environment of this kind of optical cable is much worse than pipeline laying and direct burial laying. The underwater optical cable must adopt a steel wire or steel tape armored structure, and the structure of the sheath must be considered comprehensively according to the hydrogeological conditions of the river. Submarine optical cables are also underwater cables, but the laying environment conditions are more severe and more demanding than general underwater optical cables. The service life of submarine optical cable systems and their original components is required to be more than 25 years.